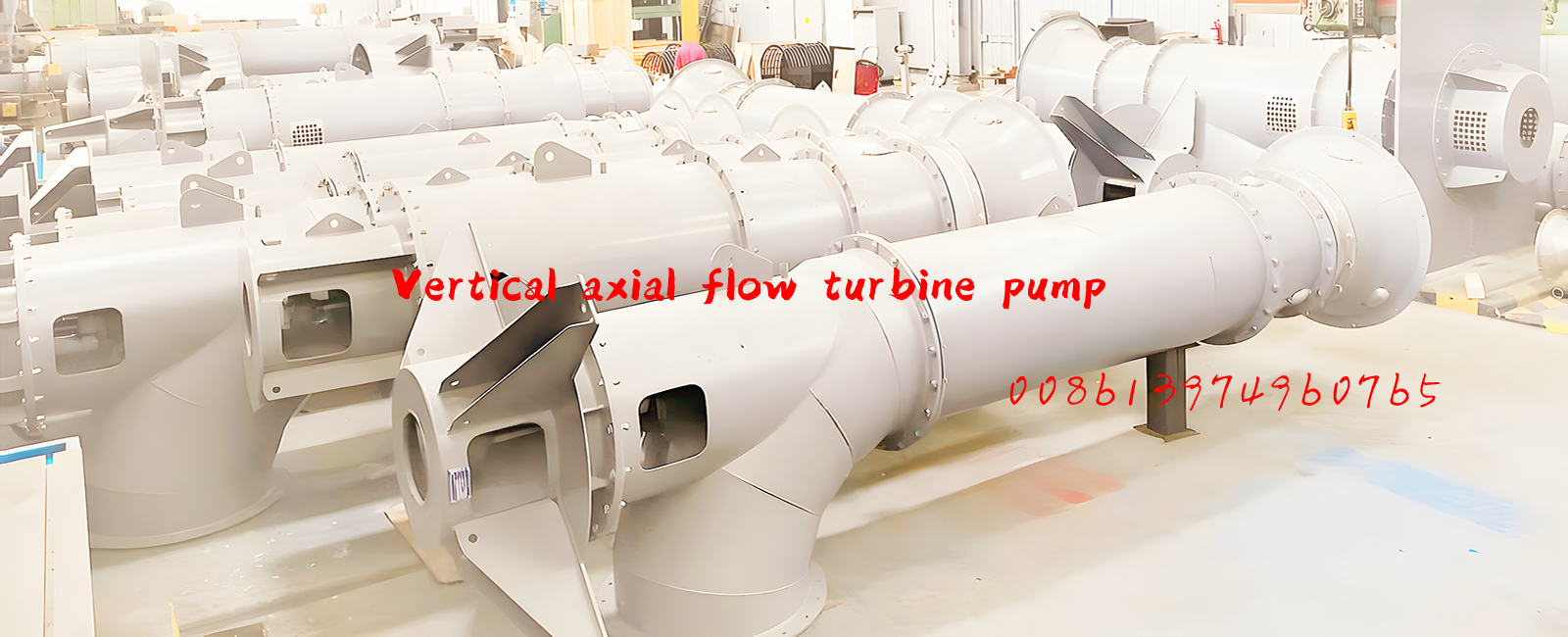

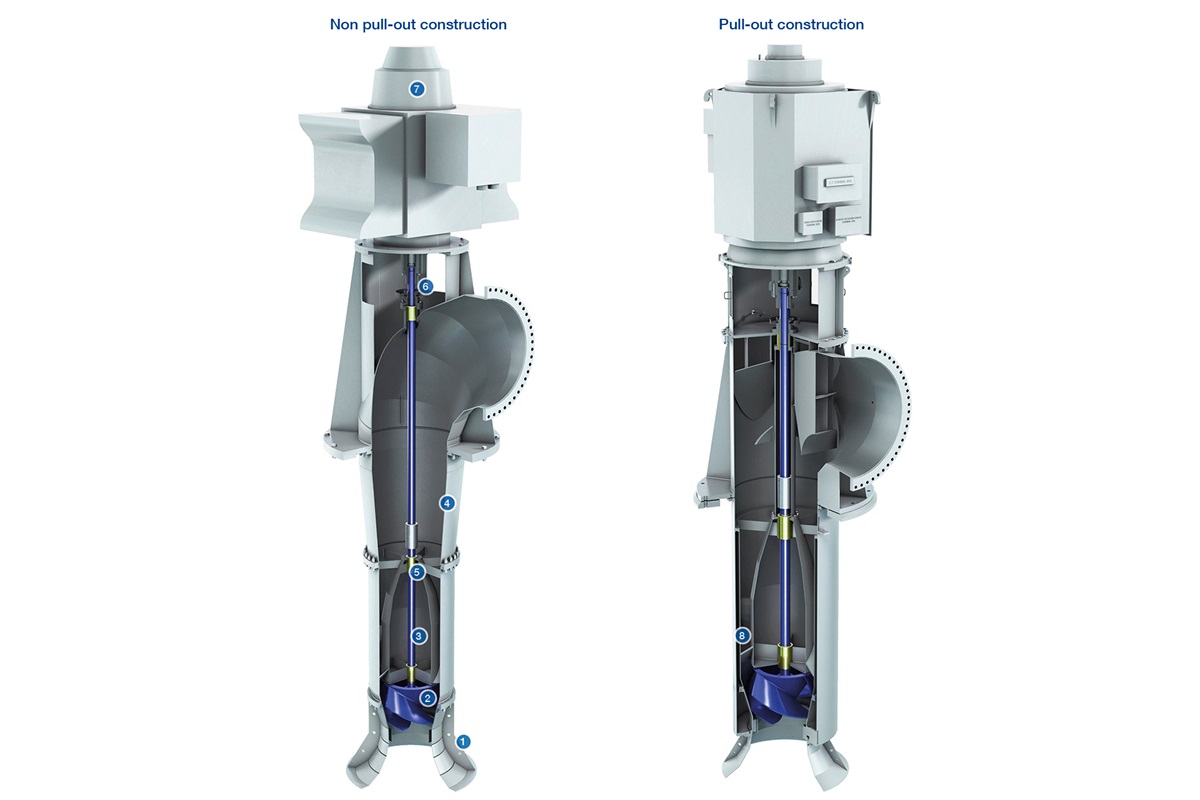

High pump efficiency

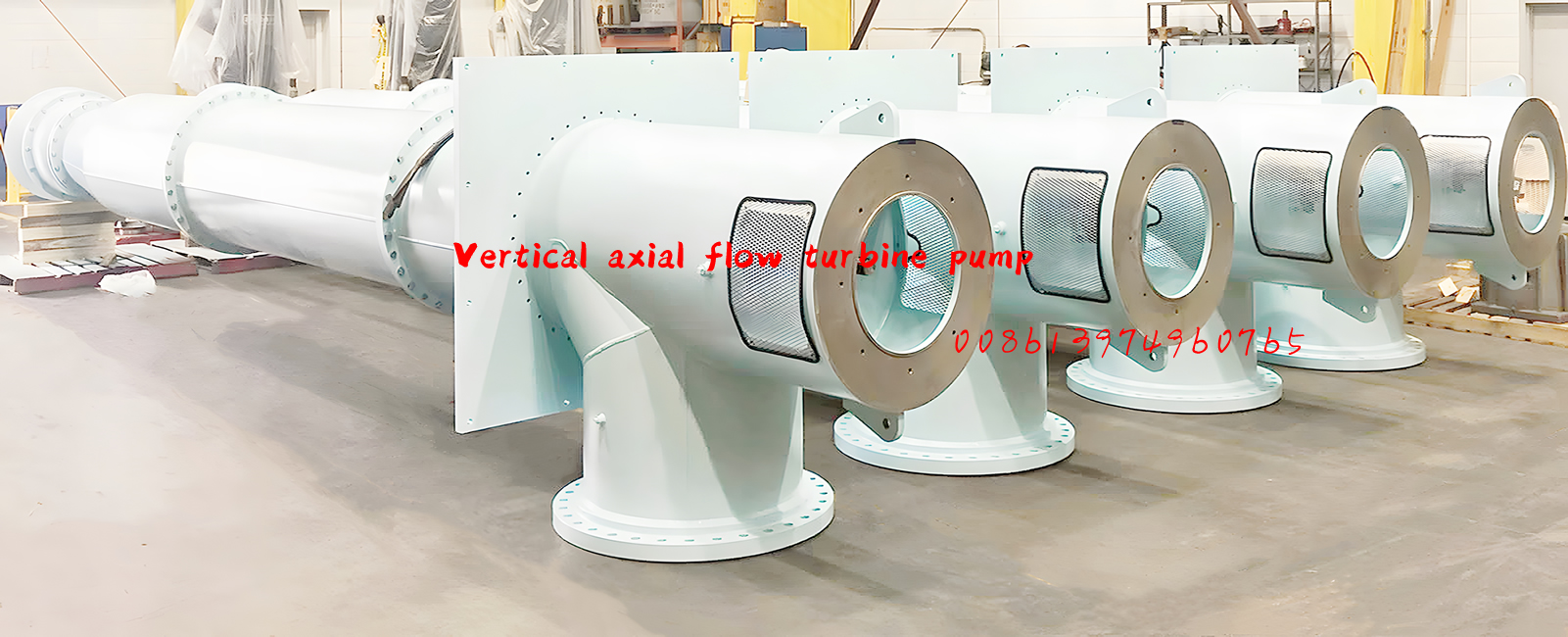

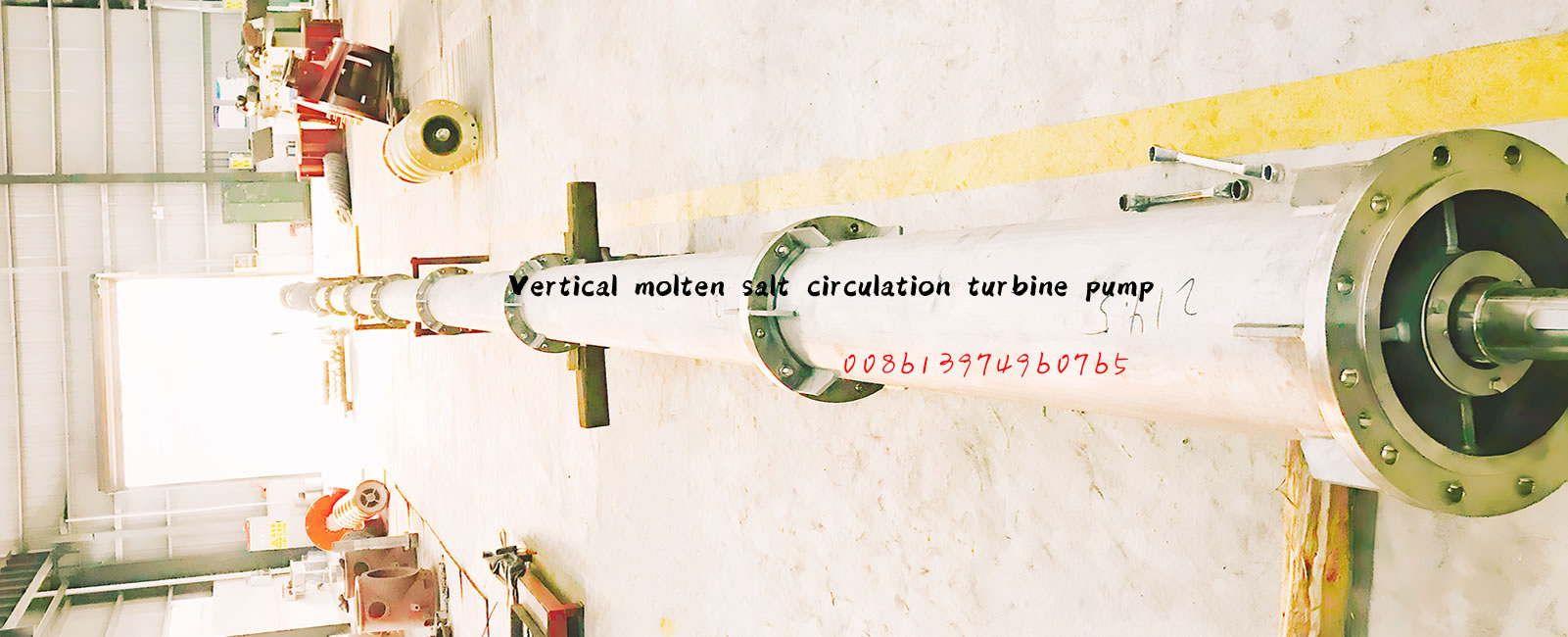

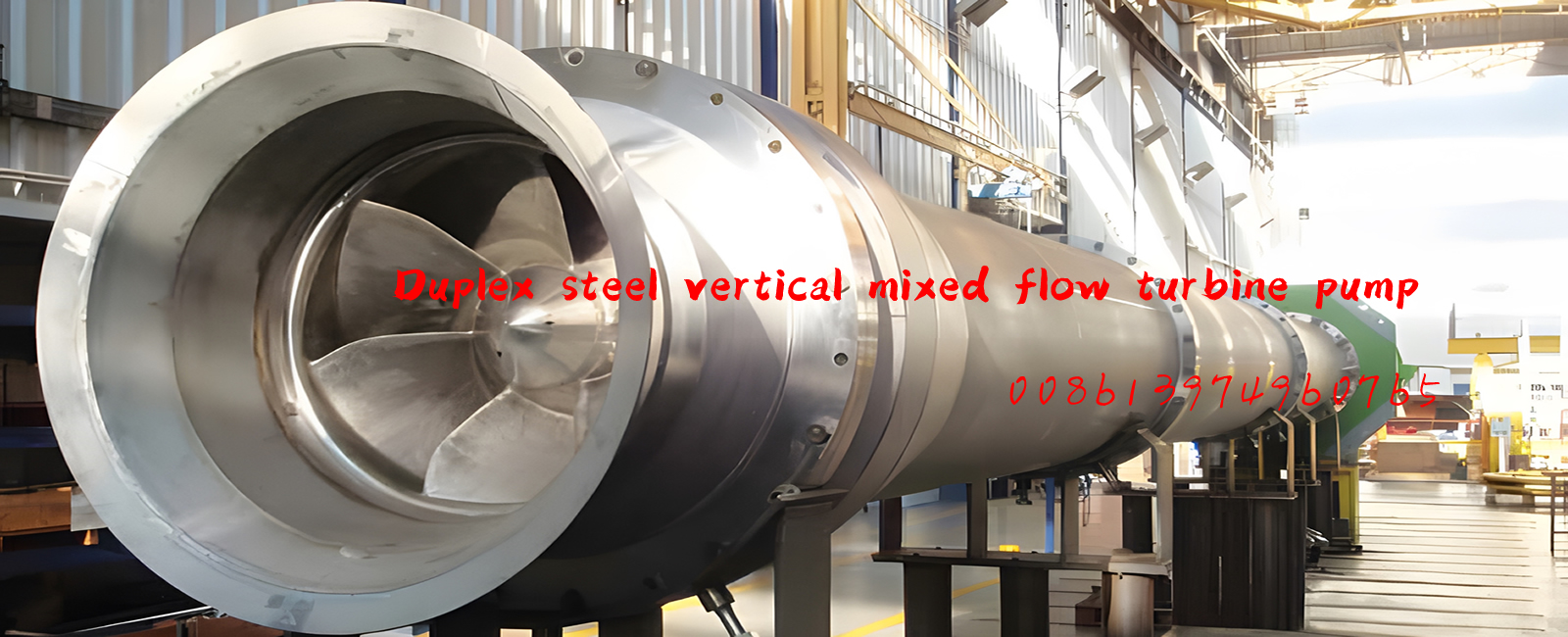

Modern fabricated suction bell and bowl casing incorporating swirl break for stable pump performance curve

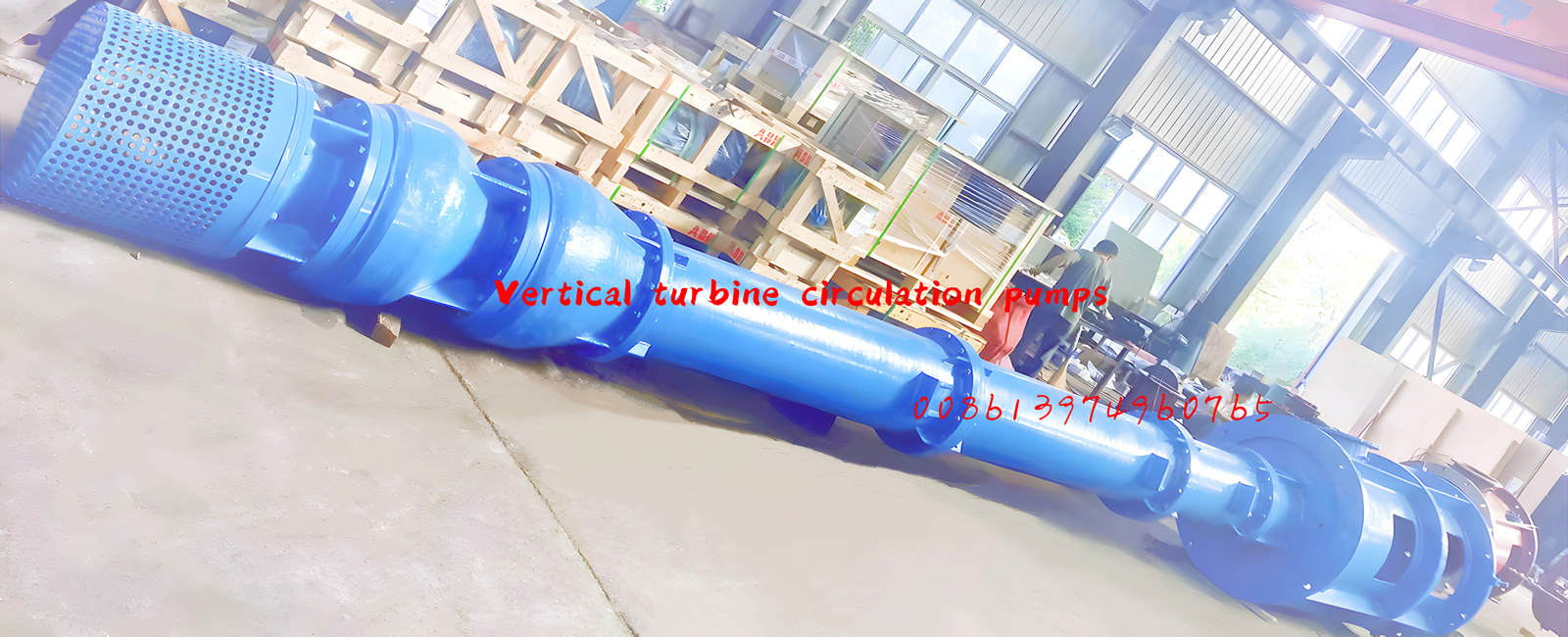

Semi-open or closed cast impeller design for best fit and optimum efficiency

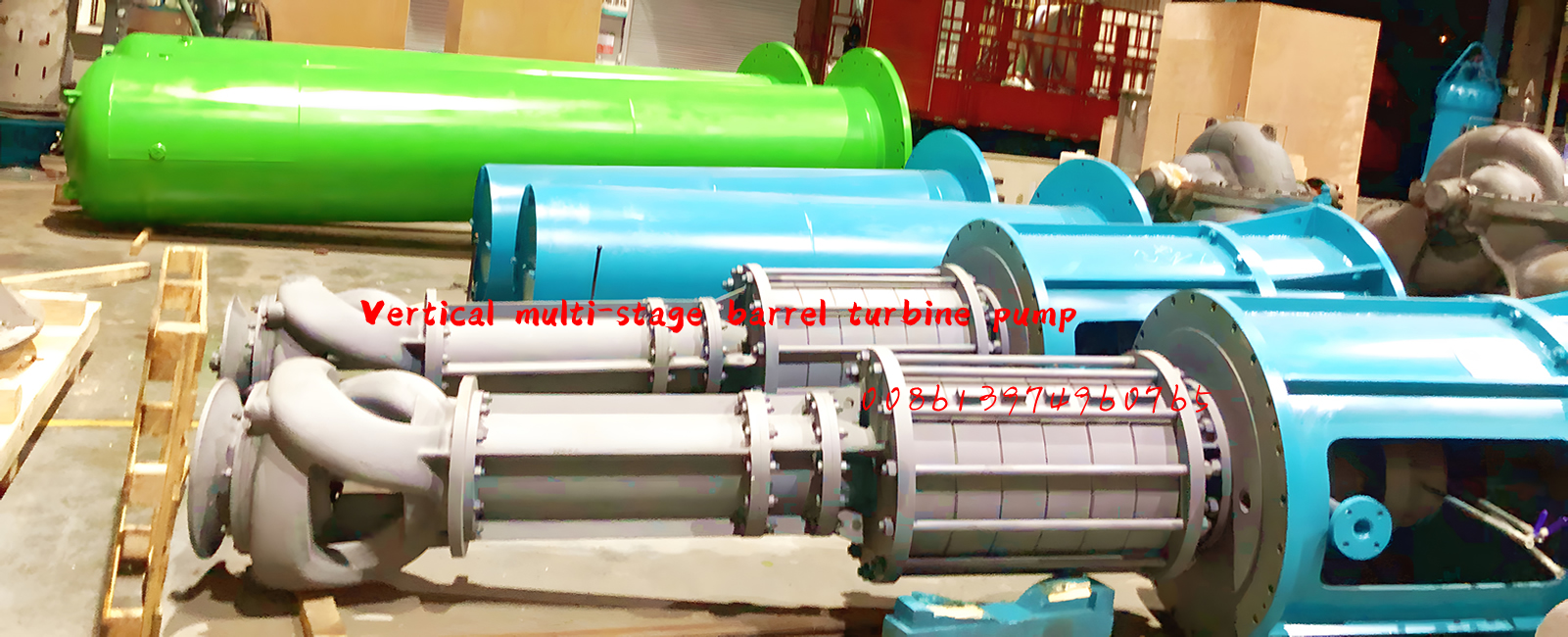

Segmented elbow to optimize pump efficiency

Optional full pull-out construction to reduce lifting crane capacity and ease maintenance